Bulldog-Tough Bags You Can Rely On

Finding high-quality paper bags that can stand up to the demands of your business isn’t always easy. Too often, companies face issues with bags that tear, don’t protect their products, or fail to align with their sustainability goals.

At Bulldog Bag, we understand these challenges and offer expertly crafted paper bags that deliver on durability, reliability, and eco-friendliness. Our paper bags are designed to strengthen your brand while keeping customers satisfied.

The Dependable Choice for Exceptional Paper Bags

When you choose Bulldog Bag as your paper bag manufacturer, you partner with a team that prioritizes quality, sustainability, and customized solutions. Our paper bags are built to support your business, offering unmatched durability and versatility.

Versatile Paper Bags for Every Industry

Whether for checkout, baked goods, confections, or food services, our paper bags ensure your products are securely packaged and presented in a style that keeps your brand looking its best.

Grocery Bags

Smaller and lighter option. If you know exactly what size and weight your bags need to carry, this is likely the product line you’re looking for.

Check stand Bags

Mid range for bag size to GSM ratio. If you have a rough idea of what size bag you need but not sure what’s going inside, and want to err on the side of caution.

Hardware Bags

Thicker and heavier for dense products. If you have a good idea of the size bag you want, and know that it’s going to be a hard-working bag.

Notion Bags

PFAS free and perfect for sandwiches, confections and baked goods.

Bread Bags

The classic kraft bag, windowed bread bag or foil lined bread bags for loafs of all shapes and sizes.

Twisted Handle Bags

Frequently used in takeout and apparel, the standard square bottom bags with a twisted paper handle.

Flat Handle Bags

Our latest addition to the paper bag lineup, the standard square bottom bags with a flat folded paper handle.

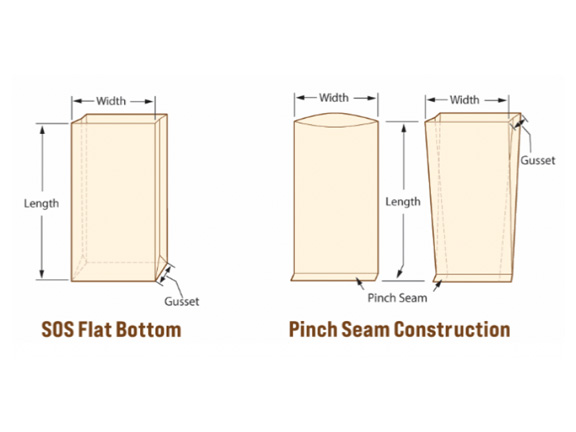

How to Measure a Paper Bag

Bag Dimensions (in.) W x Gusset x L:

When measuring a bag, the dimensions are measured by width x gusset x length.

- Width: The measurement of the face of the bag.

- Gusset: Measured by opening the sides and measuring it from edge to edge.

- Length: The measurement from the bottom of the bag to the lower lip on the face of the bag.

- GSM: The unit of measurement for the weight of a fabric, in our case paper. GSM or grams per square meter, it’s one of the properties that determine a bag’s strength. Higher GSM paper usually makes for a stronger bag, but what you gain in strength you lose in flexibility.

Commonly Used Bag Terms

Each of our products is assigned a unique Bulldog Bag product code. This code is used to identify and track specific products throughout the manufacturing and distribution process.

The Universal Product Code (UPC) is a barcode found on product packaging that helps identify the item. It typically includes a black barcode that can be scanned at checkout, along with a 12-digit number beneath it for easy identification.

In the packaging industry, bag sizes are often expressed in pound (#) sizes, which is a shorthand used within the market. These sizes used to relate to the volume or capacity that a bag can hold, but with the advent of multiwall paper bags for CPGs, these pound sizes have become more of an industry shorthand rather than actually being used for measurement.

Grams per Square Meter (GSM) is a measurement of paper weight that indicates how heavy a square meter of paper is. The higher the GSM, the heavier the paper will be. GSM is one of several attributes to consider when gauging the durability of a paper product.

In the United States, paper weight is also measured in pounds per ream. This measurement indicates how much a ream (500 sheets) of paper weighs. It’s a common unit of measure that helps determine the sturdiness of the paper used in your bags.

Pack Quantity refers to the total number of bags included in one bundle or case. For example, if the pack quantity is 500, there are 500 bags in that particular bundle or case.

Ti and Hi describe how a product is stacked on a pallet. “Ti” (Tier) indicates the number of bundles on each layer of the pallet, while “Hi” (Height) refers to the number of layers stacked on top of each other. This helps ensure efficient use of space during shipping and storage.

Pack Weight is the total weight of a full bundle, measured in pounds. This information is crucial for handling, shipping, and storage considerations.

A case refers to a box in which bags are packaged, while a bundle is typically strapped with plastic ties. Knowing the difference helps you understand how your products will be packaged and delivered.

Pack Dimensions refer to the length, width, and height of a bundle or case. These dimensions are important for storage planning, shipping logistics, and ensuring your products fit within designated spaces.

Pallet Quantity is the total number of bags stacked on a single pallet. Understanding pallet quantity helps manage inventory levels and plan transport and storage.

Industry Insights

Explore our rich collection of resources to stay ahead of the curve with the latest trends and strategies in packaging solutions.